Location -> News

News

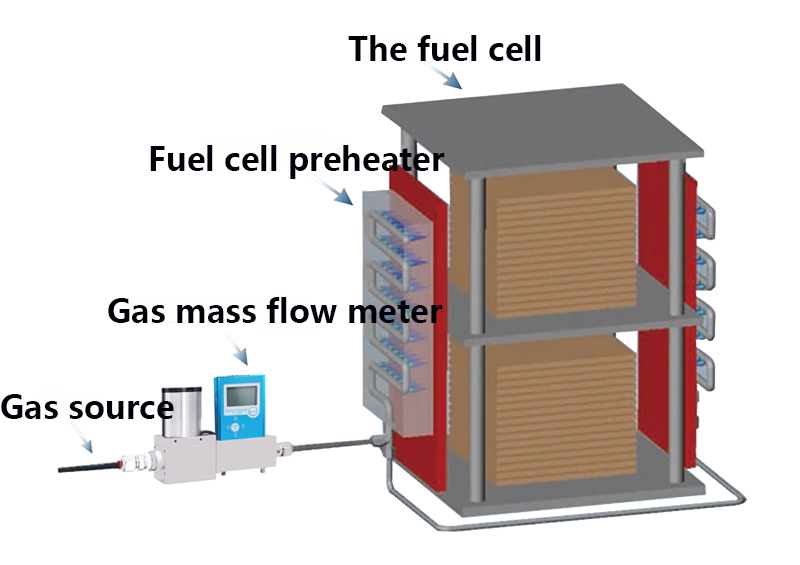

Gas mass flow meter in Solid Oxide Fuel Cell Application

In traditional fuel cell stacks, gas flow meter is often used to adjust the flow of gas fuel into the preheater (hydrocarbon fuel system), or to adjust the hydrogen and air

or oxygen directly entering the stack.

The solid oxide fuel cell stack also needs to be warmed up before turning on the generator. In the transient change from room temperature to operating temperature,

controlling the rate of temperature rise is essential to prevent damage to the battery stack.

sales01@cxflowmeter.com

or oxygen directly entering the stack.

The solid oxide fuel cell stack also needs to be warmed up before turning on the generator. In the transient change from room temperature to operating temperature,

controlling the rate of temperature rise is essential to prevent damage to the battery stack.

sales01@cxflowmeter.com

Generally speaking, the catastrophic loss of the fuel cell stack is caused by the failure of auxiliary equipment. In the case of uneven heating or rapid heating, the battery

stack is particularly prone to cracking. The gas mass flow controller provides fast and precise control and ensures that the battery stack is not damaged by thermal transients when the device is started.

stack is particularly prone to cracking. The gas mass flow controller provides fast and precise control and ensures that the battery stack is not damaged by thermal transients when the device is started.

When the RS-232 set point signal is used as the driving signal, the gas quality controller increases by 1/64,000 of the full scale to adjust the amount of fuel burned per

unit time at any time. Using a computer to directly monitor the temperature of the battery stack can ensure that the temperature reaches the target smoothly.

unit time at any time. Using a computer to directly monitor the temperature of the battery stack can ensure that the temperature reaches the target smoothly.

The Shanghai CIXI Gas Flow meter has inherent high frequency and can respond quickly to transient changes in gas source pressure. The controller can complete

the following actions about 1000 times per second: read out the flow rate, calibrate the driver to control the valve. In this way, the transient change of the air source pressure

can be quickly compensated. In general, the response time is less than 50mS.

For more information, please contact winny: sales01@cxflowmeter.com

the following actions about 1000 times per second: read out the flow rate, calibrate the driver to control the valve. In this way, the transient change of the air source pressure

can be quickly compensated. In general, the response time is less than 50mS.

For more information, please contact winny: sales01@cxflowmeter.com

Last:Application of ultrasonic flow .. Next:Chemical Liquid Viscosity Table